we specialize in manufacturing high-quality pharmaceutical plastic containers designed to meet the rigorous standards of the pharmaceutical industry. Our Pharmaceutical plastic containers ensure the safe storage and transport of medicines and health products, offering both functionality and reliability. Our commitment to quality, innovation, and customer satisfaction makes us a trusted partner for pharmaceutical packaging needs, with customization options available to suit your specific requirements.

Pharmaceutical Plastic Container

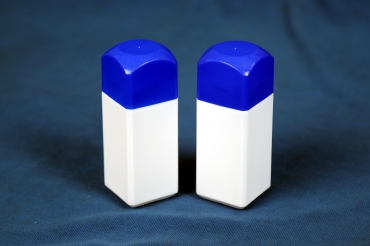

Plastic Square Powder Container

Marking : 75 gm

Colour : White with blue cap and Plug

Plastic Square Powder Container

Marking : 100 gm

Colour : White with blue cap and Plug

Plastic Tablet Container

Marking : 20 ml,

Colour : White

Plastic Round Powder Container

Size: 30 gm

Colour : White with red cap and plug

Plastic Round Powder Container

Marking : 75 gm

Colour : White with red cap and plug

Plastic Round Powder Container

Size: 100 gm

Colour : White with red cap and plug

Plastic Triangular Tablet Container 40 ml

Size: 40 ml / 31 mm with cap

Colour : Milky White

Plastic Round Tablet Container 20 ml

Size: 20 ml / 29 mm with cap

Colour : Milky White

Plastic Round Tablet Container 40 ml

Size: 40 ml with Cap

Colour : Milky White

Plastic Round Tablet Container 20 ml (CRC Cap)

Size: 20 ml / 28 mm with CRC cap

Colour : Milky White

Plastic Round Tablet Container 60 ml (CRC Cap)

Size: 60 ml / 37 mm with cap

Colour : Milky White

Plastic Round Tablet Container 100 ml (CRC Cap)

Size: 100 ml / 37 mm with CRC cap

Colour : Milky White

Plastic pharmaceutical packaging from Dabar Pack , which includes a range of bottles, Balm Bottel, rounds, and plastic containers, is produced in large quantities. Our skilled team of technologists and designers creates our pharmaceutical plastic packaging to satisfy healthcare providers’ specifications.

Utilise a Pharmaceutical plastic container from Dabar Pack to find the ideal storage option for all of your medical pills, capsules, powders, liquids, and chemicals. Our pharmaceutical plastic container ,Plastic Round Tablet Container, Plastic Triangular Tablet Container ,Plastic Round Powder Container are made to keep and safeguard medications, oils, and other items.

Every Dabar pack plastic container is created at one of our premier key production locations. Our hard-working staff is committed to developing new products and is constantly looking for methods to cut costs, increase design and manufacturing efficiency, and maintain the exacting standards needed for pharmaceutical packaging.

The Production Technologies of Plastic Pharmaceutical Packaging Container

Pharmaceutical plastic packaging is produced using five distinct technologies:

- Compression (CM): The molten polymer is combined inside a plasticising unit, sliced into the proper size pellets, and then fed into a machine with several cavities. Here, the material is printed and turned into the desired object through an ongoing labour cycle. Compression is the primary method used to create caps and closures.

- Injection moulding (IM): The process of melting and injecting plastic material into a mould, which then opens and releases the produced object

- Injection moulding (IM): The process of melting and injecting plastic material into a mould, which then opens and releases the produced object, is known as injection moulding (IM).

- Injection-stretch-blow moulding (ISBM): Injection-stretch-blow moulding (ISBM) uses a piston to stretch and elongate the product to the required size in addition to a compressed air jet to inflate the object. This method allows for the production of large-capacity bottles and bottles in a variety of forms for pills.

The Quality of Plastic Pharmaceutical Packaging

In the pharmaceutical industry, plastic pharmaceutical packaging containers play a vital role in safeguarding medications and medical products. Ensuring the highest standards of quality for these containers is critical to maintaining the safety, efficacy, and stability of the pharmaceutical contents they store. Here’s why the quality of plastic pharmaceutical containers is essential, and the key factors that contribute to their reliability.

The quality of plastic pharmaceutical packaging is critical to ensuring the safety and effectiveness of medicinal products. High-quality packaging must offer durability, chemical resistance, and protection against external factors such as moisture, light, and contamination. Materials like polyethylene (PE) and polypropylene (PP) are commonly used due to their inert properties, preventing interactions with the contents inside. Packaging is rigorously tested to ensure it meets industry standards for sterility, tamper-evidence, and child-resistant features. Additionally, Good Manufacturing Practices (GMP) are strictly followed to maintain consistency and quality in production. Quality control measures, including mechanical testing for strength and barrier properties, as well as visual inspections for defects, ensure that the packaging maintains its integrity throughout the product’s lifecycle, from manufacturing to the end consumer.

. High-Quality Materials for Plastic Pharmaceutical Packaging

The foundation of any pharmaceutical plastic container is the material it’s made from. Common materials such as HDPE (High-Density Polyethylene), PP (Polypropylene), and PET (Polyethylene Terephthalate) are frequently used due to their non-reactive properties. These materials prevent interactions between the container and the pharmaceutical product, ensuring that the product remains stable and safe for consumption.

. Ensuring Sterility in Pharmaceutical Plastic Containers

For certain medications, maintaining sterility is essential. Sterilized pharmaceutical plastic containers help ensure that the product is free from microbial contamination. Proper sterilization procedures and packaging designs contribute to keeping the medication safe for patient use.

Plastic containers for medicines and cosmetics

Certain plastics guarantee the preservation of product quality and wholesomeness and are specifically made for use in medicine. Physicians advocate certain polymers in particular, particularly those that are inert, do not distort, and do not release compounds that could harm a product’s active contents. Drugstore packaging can be found in plastic containers comprised of polyethylene, polystyrene, polypropylene, and polyvinyl chloride. Among other plastics that are safe for pharmacies and appropriate for certain substances are polymethyl methacrylates and polyethylene terephthalate.

Plastic containers are specifically designed to enable the deployment of new care therapies in situations where a dispenser or specific hospital use characteristics are required. In this situation, the efforts of the plastics industry technicians who supply qualified medical professionals are valuable because they enable you to select a particular product and the most appropriate packing material that guarantees the security and effectiveness of treatment information.